All Section of Factory

Natanz Steel Complex is a fully technical and specialized complex that includes smelting unit and ingot production lines and rolling units. In the following, you will get to know the parts of this collection.

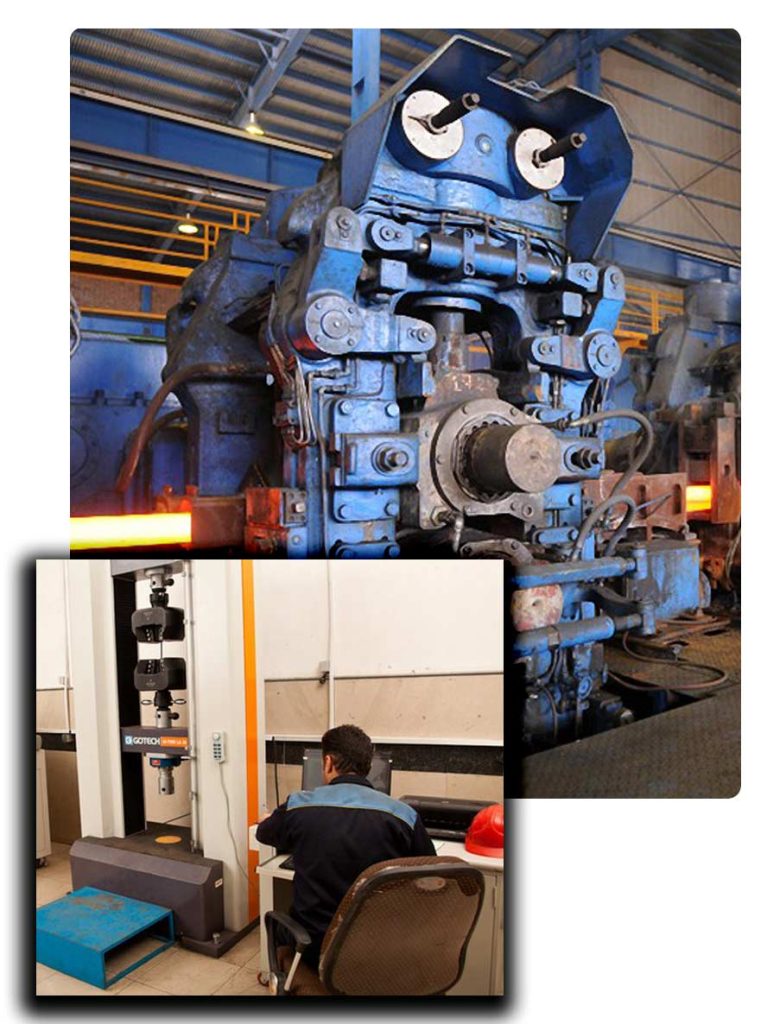

In this factory, using modern technology, simple and ribbed bars, A2, A3 and A4, from 8 to 32 mm in size are produced in the form of branches. The equipment of this factory, which was purchased from Danieli Italy, was put into operation after installation in February of 2012.

Natanz Steel Company, which was established with the purpose of producing a variety of industrial and construction rebar baskets and supplying raw materials to wire industry units, after setting up the rebar rolling line factory in the branch to Mantur, to meet the needs of downstream steel industries and also with the aim of developing exports

Branch unit

According to the needs of customers for 8, 10, and 12 mm branch bars, this company decided to set up a branching unit to convert the rebar produced by its rebar rolling line factory into branches, and in this regard, 9 branching lines with modern European technology were purchased and installed.

In the smelting unit, sponge iron and other ferroalloys are converted into molten materials and transferred to LF and VOD furnaces, and then by continuous casting machine, the molten materials are converted into steel ingots and the produced ingots are ready to be sent to the market. is .

About Us

Introduction of Natanz steel complex

Natanz Steel Complex started its activity in the late forties on Pamnar Street in Tehran by selling construction iron and in the early fifties, along with trade in the industrial sector, it expanded its activity by producing steel products and established the Natanz Steel Factories Complex. they did

By combining science and experience with the production of all kinds of industrial, construction, reinforcement wires, etc., they created a new development in the field of diverse products in this field and subsequently in a short period of time they were able to play a decisive role in the wire industry sector in the production and To perform sales market.

Natanz steel company started its activity in the form of development of Natanz steel factories with the aim of producing all kinds of industrial and construction rebars and supplying raw materials for wire industries and creating employment in the region and the country in 1378 and in February of 1382 it was able to start the first phase of production Put the factory into operation.

Latest Technology

Natanz steel complex

Engineering production along with safety and pollution control;

- Quality control laboratory

- Occupational health and safety

- Environmental monitoring

These are the three important parts, along with the main production parts and rebar and coil rolling lines, which are very important and sensitive in Natanz Steel Complex.

At Natanz Steel Complex, we do our best to properly manage waste, reduce environmental emissions, and use green and clean technologies to help preserve the environment.

span>We use advanced safety equipment and processes and have taken the necessary measures to reduce work accidents and maintain the health of employees and work hygiene.

The quality control laboratory uses advanced equipment and detailed processes to check and improve the quality of products so that our customers can benefit from high quality products.< /p>

Contracting party companies and organizations